High-Power Thin Film Resistors

Click To Enlarge

Download

Vishay Specialty Thin Film

Resistors / Substrates

Vishay Specialty Thin Film delivers a powerhouse portfolio of high-performance thin film solutions—including Chip Resistors, MOS Chip Capacitors, Spiral Chip Inductors, and Substrates—engineered for precision and reliability. With one of the industry’s broadest selections, Vishay Specialty Thin Film gives engineers the flexibility to source exactly what they need for custom, high-reliability designs. When it comes to thin film technology, Vishay doesn’t just participate—they lead."

ES Components “Off-The-Shelf” Inventory

-

ES Components Electro-Films' "Off-The-Shelf" Inventory offers a convenient and cost-effective solution for customers, providing quick access to the most popular devices with no minimum order quantities and 24-hour delivery. This allows designers to replenish their inventory without committing to large quantities, making it an attractive option for prototype development and small-scale production. Additionally, the "Off-The-Shelf" inventory enables design-in and production ramp-up at economical low volume pricing, providing flexibility and mitigating lead time risks.

Vishay Specialty Thin Film Chip Components

-

Substrate Materials: Silicon, Alumina, Quartz, BeO, AIN

Resistor Films: Tantalum Nitride, Nickel Chromium

Contact Metallizations: Wirebondable Gold, Wirebondable Aluminum, Solderable Gold, Solder Dipped

-

Case Sizes: Range From 015015 to 0808

Resistance Values: Range From 1 MΩ to 20 MΩ

TCR: As Low as ± 25 ppm /°C

Tolerance: As Low as ± 0,1 %

-

Capacitance Values: Range From 0.25 pF to 1000 pF

Tolerance As Low As 0.05 pF

MOS and MNOS: Dielectric Options

Inductance Values: Range From 3.9 nH to 30 nH In Increments

-

Vishay EFI Specializes In High Frequency Products

Measured Frequency Up To 20 GHz

High Frequency Products Available In Resistors, Capacitors, and Spiral Inductors

-

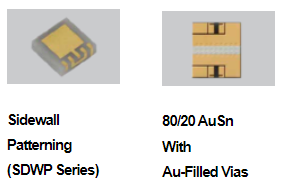

Vishay EFI Also Offers Custom-Designed Submount Options

Assembly Options: Wirebondable, Solderable, Epoxy-Attach

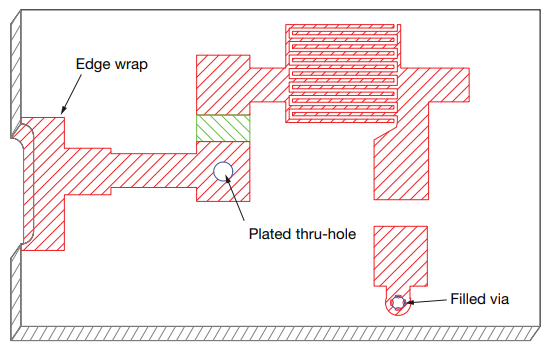

Capabilities: Side-Wall Patterning, AuSn, Au-Filled Vias, Edge Wraps, Air-Bridges, and Laser-Machined Custom Substrates

Chip Resistors 🔹Chip Capacitors 🔹Spiral Inductors 🔹Microwave High Power 🔹Substrates

-

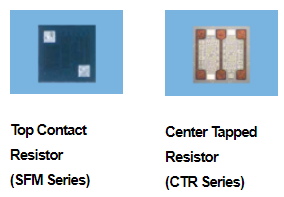

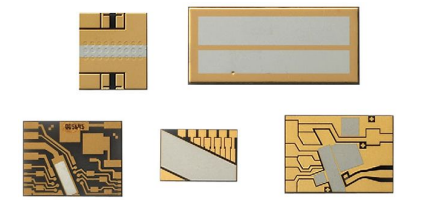

VISHAY EFI CHIP RESISTORS

Vishay EFI offers a variety of sizes and solutions for chip and wire assembly needs. Vishay single value wire bondable chip resistors are available on silicon, alumina, or quartz. Silicon substrates offer the highest power handling while quartz and alumina substrates have lower parasitic capacitance between the resistors and mounting board. Single value chip resistors are available with a back contact option, which reduces the number of wire bonds from two to one. Ranging in case sizes of 0201 to 1206, the resistor chips offer wire bondable terminations in Au or Al with options for backside

metallization for various attachment methods.

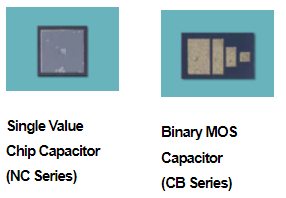

See Data SheetsVISHAY EFI CHIP CAPACITORS

Vishay EFI wire bondable Metal Oxide Silicon (MOS) / Metal Nitride Oxide Silicon (MNOS) capacitors offer a small size, thin film option. Vishay EFI manufactures top contact single value thin film chip capacitors with silicon dioxide and silicon nitride dielectric on a silicon substrate. The top termination is available as either sputtered aluminum or plated gold and the backside metal is sputtered gold for mounting with conductive epoxy or some solders. EFI also produces binary MOS multi-value capacitor chips which allow the user many choices in value selection. Custom capacitor networks are another option, either by customer drawing or through collaboration

with the Vishay EFI design team.

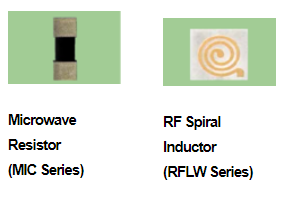

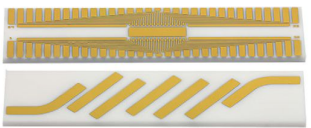

See Data SheetsVISHAY EFI SPIRAL INDUCTORS

Vishay EFI offers thin film wire bondable spiral inductors on quartz or alumina substrates. The spiral inductors are used in RF designs and circuits that require wire bondability. The Vishay EFI Chip Inductor has low DC Resistance (DCR), low parasitic capacitance, high quality factor or Q factor and high Self Resonant Frequency (SRF). Available in case sizes from 0303 to 0505, these parts are perfect for space

saving applications in the RF industry.

See Data Sheets

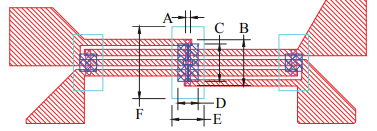

VISHAY EFI MICROWAVE HIGH POWER

Vishay EFI high frequency products include chip resistors, resistor arrays and tapped resistors all on a alumina substrate and the spiral chip inductor on quartz. The chip resistors are available with wire bondable or solderable terminations which can also be used as a flip chip. The microwave products provide excellent high-frequency response and are typically used in applications for Amplifiers, Oscillators, Attenuators and more. Please reference additional information in our High Frequency Brochure. The high power wire bondable resistor product families offer the highest power in a small footprint. These resistors are available with both back contact and top contact configurations. The power handling ratings range from 500mW up to 4 W of power. The high temperature wire bondable resistors are designed

to operate in environments up to 250 °C

See Data Sheets

VISHAY EFI SUBSTRATES

Vishay EFI offers a variety of substrates for custom thin film solutions. The three substrates mainly used in our custom solutions are Alumina (Al2O3), Aluminum Nitride (AlN) and Beryllium Oxide (BeO) either lapped, as-fired or polished surface finishes. Alumina is a cost-effective solution that is commonly used for its surface quality and high frequency performance. For power applications and when high thermal conductivity is needed, AlN and BeO substrates are optimal. Important factors to consider when choosing a substrate include dielectric constant, surface finish, loss tangent, thermal conductivity, coefficient of thermal expansion and cost. Vishay EFI produces on substrates that range in thickness from 5 mils to 60 mils and range in size from 20 x 20 mils to 4.50 in x 4.50 in.

See Data Sheets

Enhance Performance with

Vishay’s High-Quality Custom Substrates

Enhance your designs with Vishay’s high-quality custom substrates, engineered for superior thermal management, reliability, and precision. Tailored to meet your exact specifications, these advanced substrates optimize performance in demanding aerospace, military, medical, and industrial applications. Maximize efficiency and durability with Vishay’s trusted solutions.

Substrate Layout Guidelines

🔹Standard Substrates

🔹Silicon Substrates

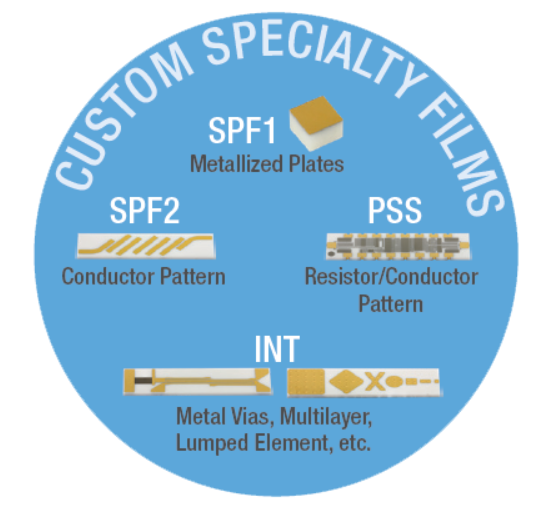

Custom Specialty Films

Custom Substrates 🔹Build To Print Ceramic Solutions

Capabilities

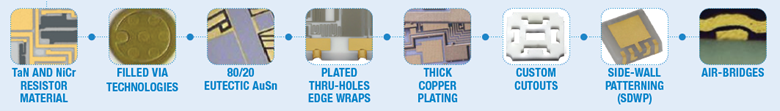

-

Sputtered Metals

🔹Adhesion Layer - Chrome (Cr), Titanium Tungsten (TiW)

🔹Barrier Layer - Palladium (Pd), Nickel (Ni)

🔹Conductor Layer - Aluminum (Al), Gold (Au), Copper (Cu)

🔹Solder Layer - Gold Tin (AuSn)Plated Metals

🔹Barrier Layer - Nickel (Ni)

🔹Conductor Layer - Gold (Au), Copper (Cu)

🔹High Current Conductor - Gold (Au), Copper (Cu)Substrate Materials

🔹Alumina (Al203)

🔹Aluminum Nitride (AIN)

🔹Beryllium Oxide (BeO)

🔹Silicon (Si)

🔹Quartz (SiO2)

🔹Other: Titanates, Ferrites, Sapphire

Thin Film Substrates

Thin Film Design Guide for Custom Substrates

Capabilities /Features

-

• Choosing a substrate

• Defining a metal system

• Integrating thin film resistors

• Designing with vias

• Incorporating high conductivity traces

• Use of multi-layer thin films

• Substrate singulation

Custom Substrates

Hybrid & Microwave Applications - Conductor Pattern

Capabilities /Features

-

FEATURES

• Precision conductor patterns

• Metalization on 1 or 2 surfaces

• Various substrate materials

• Sputtered / plated metal systems • Custom sizes from 0.020" x 0.020" to 4.000" x 4.000"

• Quick delivery available

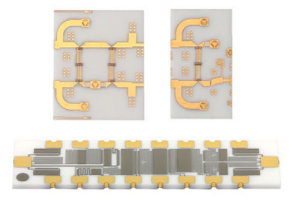

Custom Substrates - Multilayer

Metal Via / Multilayer / Lumped Element

Capabilities / Features

-

FEATURES

• Plated or filled via technology

• Mulitlayer and overcoat patterning

• Lumped element custom substrates

• Al2O3, AlN, and BeO substrate drilling and shaping

• TaN and NiCr resistor films

• Metallization on 1,2, or 4 surfaces • Various substrate materials

• Sputtered / plated metal systems • Custom sizes from 0.020" x 0.020" to 4.000" x 4.000"

• Quick delivery available